DLT Engineering

Product Page

Product Page

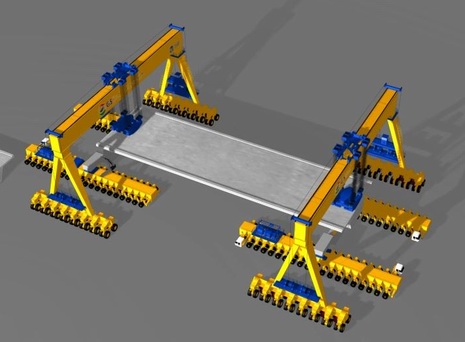

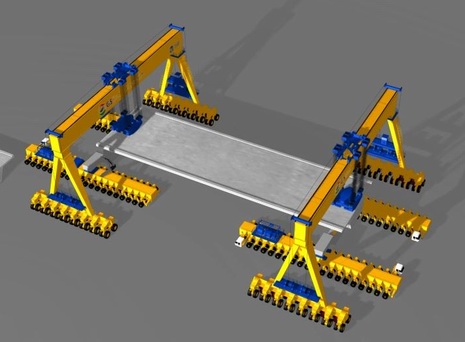

DLT Straddle Carriers

DLT straddle carriers are intended for use on construction sites and assembly yards for the movement of heavy precast or prefabricated items such as bridge deck beams or precast bridge foundations and piers. DLT straddle carriers comprise a portal crane mounted on multiple axle lines of pneumatic tyres and combine the benefits of an overhead goliath crane with the manoeuvrability of a multi-axle steerable transporter. A single straddle carrier is able to do the work of multiple rail based cranes and skidding/transport systems due the high manoeuvrability, and therefore offer a very economic solution.

DLT straddle carriers are able to steer in any direction, and are able to turn the axles through 90 degrees whilst fully loaded for an on the spot 90 degree direction change. Multiple straddle carriers can be used together to handle long loads, with central control. The axles of the straddle carrier are hydraulically linked for even loading and are articulated to cope with uneven ground without generating additional loads in the tyres. Typically the straddle carrier will exert a general ground bearing pressure of 10 to 15 tonnes/m2 and a local contact pressure under the tyres of 0.4 to 0.6 MPa. On a typical site the ground preparation needed under the straddle carrier running route will be a layer of compacted crushed rock or a reinforced concrete ground bearing slab.

DLT straddle carriers are able to steer in any direction, and are able to turn the axles through 90 degrees whilst fully loaded for an on the spot 90 degree direction change. Multiple straddle carriers can be used together to handle long loads, with central control. The axles of the straddle carrier are hydraulically linked for even loading and are articulated to cope with uneven ground without generating additional loads in the tyres. Typically the straddle carrier will exert a general ground bearing pressure of 10 to 15 tonnes/m2 and a local contact pressure under the tyres of 0.4 to 0.6 MPa. On a typical site the ground preparation needed under the straddle carrier running route will be a layer of compacted crushed rock or a reinforced concrete ground bearing slab.

The main features of DLT straddle carriers are as follows :

- Capacities from 100 tonnes to 3000 tonnes per straddle carrier

- Height under hook from 10 m to 60 m

- Travelling speed up to 10 km/hr fully loaded

- Designed and manufactured to European standards

- Fully steerable in all directions

- Able to make a 90 degree on the spot direction change whilst fully loaded

- Central monitoring and control of all systems

- Synchronised operation of multiple straddle carriers handling a single load

- Latest winch systems for fast and accurate positioning of the load

- Strand jack lifting systems offered as an option for larger capacities

- Low ground bearing pressure

- 2 leg and 4 leg options

Plan movement options, with improved ground shown in grey.

Animation of a typical operating sequence .

2 No 260 MT x 25m high for the Riyadh Metro project, KSA, 2015.

Read more »

2 No 850 MT x 18m high for the Doha Link project, Kuwait, 2015.

Read more »

4 leg 900 tonne capacity straddle carrier,China 2010.

2 leg 900 tonne straddle carrier, China 2009.

4 leg 900 tonne straddle carrier in a bridge site casting yard, China 2010.